Spherical Plain Radial Bearings in Auto Suspension

Mar 26,2025

Mar 26,2025

WYOO

WYOO

Industry Background

The automotive industry is constantly evolving, with a focus on improving ride comfort, handling performance, and vehicle safety. Suspension systems are critical components that connect the vehicle's body to its wheels, absorbing shocks from the road surface and ensuring proper tire contact with the ground. As vehicles become more sophisticated, the demand for high - quality suspension components, including bearings, has grown.

Application in a High - Performance Sedan's Suspension

In a high - performance sedan, the front and rear suspension systems use spherical plain radial bearings in the control arms. These bearings allow for smooth articulation of the control arms as the wheels move up and down in response to road irregularities. The spherical design enables the bearing to accommodate misalignments that occur during vehicle operation, providing better handling and stability.

Problem Encountered

In some high - performance driving scenarios, such as aggressive cornering and high - speed driving on uneven roads, the standard spherical plain radial bearings in the suspension system were prone to wear and noise generation. The high lateral forces during cornering put additional stress on the bearings, causing the sliding surfaces to wear out faster. This not only affected the ride quality but also compromised the vehicle's handling characteristics.

Solution

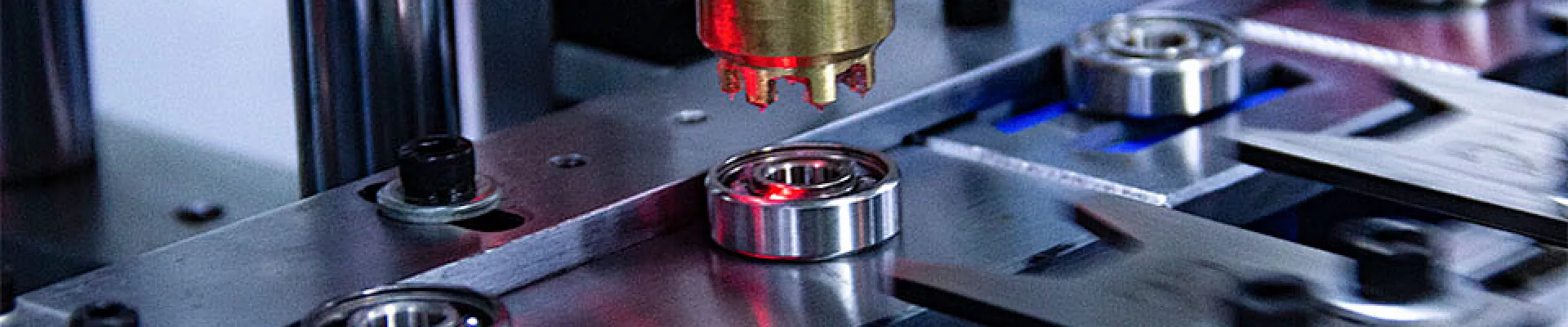

Automotive engineers developed a new generation of spherical plain radial bearings for suspension applications. These bearings featured a unique multi - layer construction. The inner and outer races were made of hardened steel, while the intermediate layer was a self - lubricating material with high load - carrying capacity. The self - lubricating property reduced the need for external lubrication and minimized friction, even under high - stress conditions. Additionally, the bearing's design was optimized to better withstand the dynamic loads experienced in high - performance driving.

Results

With the new spherical plain radial bearings installed, the high - performance sedan showed a significant improvement in handling. The wear rate of the bearings decreased by 60%, leading to a longer service life. Noise levels during suspension operation were reduced by 30%, enhancing the overall driving experience. The improved bearings also contributed to better tire wear distribution, as the suspension system could more effectively maintain proper wheel alignment during various driving conditions.

HOME

HOME Spherical Plain Radial Bearings in Industrial Robotics

Spherical Plain Radial Bearings in Industrial Robotics  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk