Rod End Bearings in Industrial Automation

Jan 15,2025

Jan 15,2025

WYOO

WYOO

Industry Background

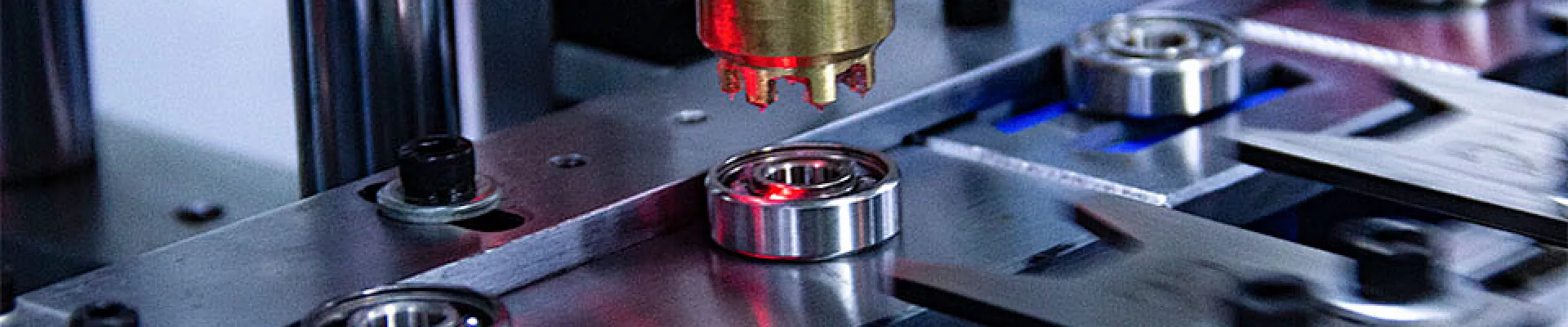

The industrial automation industry is constantly evolving, with a focus on increasing productivity, improving precision, and reducing downtime. Automated machinery, such as robotic arms and conveyor systems, requires components that can provide accurate motion and high - speed operation.

Application in a Robotic Arm

In a robotic arm used for pick - and - place operations in a factory, rod end bearings are used at the joints. These bearings enable the robotic arm to move with precision and flexibility. For example, at the elbow joint of the robotic arm, a rod end bearing allows for smooth rotation, which is crucial for the arm to reach different positions in the workspace and pick up or place objects accurately.

Technical Details and Performance

The rod end bearings in this robotic application are usually precision - engineered with low - friction materials. They are designed to operate at high speeds while maintaining high accuracy. The bearings are often pre - loaded to minimize play and ensure consistent performance. Additionally, they are made of lightweight yet strong materials to reduce the overall weight of the robotic arm, which is beneficial for energy efficiency and faster movement.

Benefits and Impact

The use of rod end bearings in the robotic arm enhances the automation process. The high - precision movement of the arm reduces errors in pick - and - place operations, improving product quality. The ability to operate at high speeds increases production output. The reliability of the rod end bearings also reduces the risk of unexpected downtime, which is costly in an industrial automation setting. Overall, the use of these bearings contributes to a more efficient and cost - effective manufacturing process.

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

204, Building B, No. 16 Caiyun Road, Jixiang Community, Longcheng Street, Longgang District, Shenzhen China 518100

HOME

HOME Rod End Bearings in Agricultural Machinery

Rod End Bearings in Agricultural Machinery

Let’s Talk

Let’s Talk